Quality in aluminum castings, production flexibility 5.0

The production process is compliant and operates according to the requirements of ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and ISO 50001:2018 standards.

All of this to ensure a quality level of casting, a distinctive characteristic of G.E.A. products worldwide.

The Foundry Division is divided into two departmens:

Shell-gravity Casting department

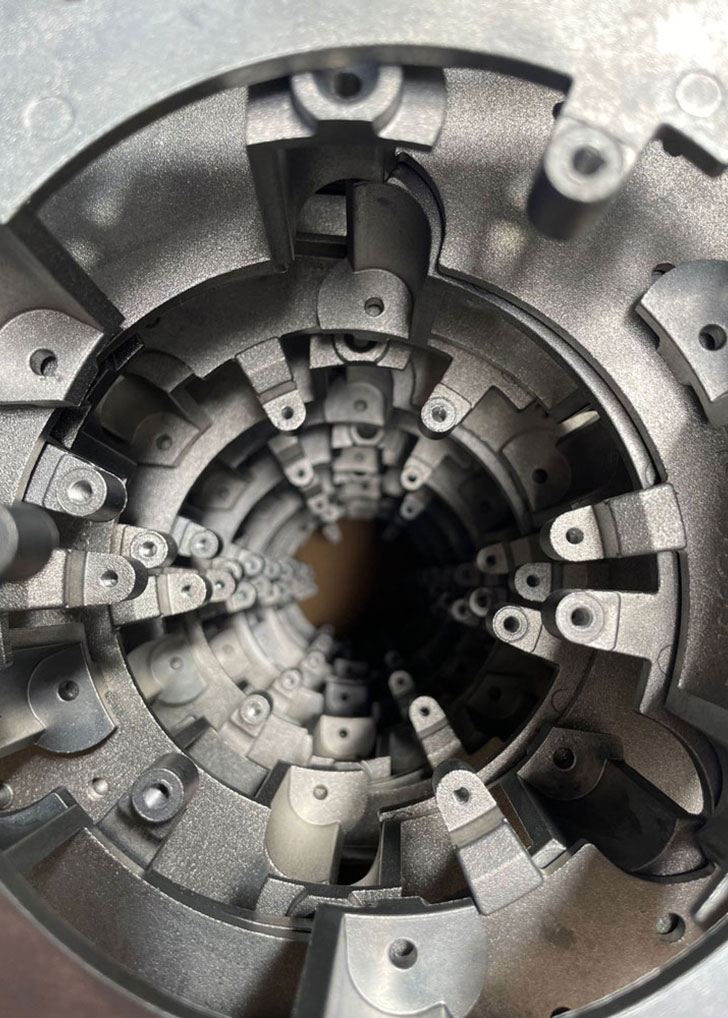

Constantly renewd, the casting department is currently equipped of 16 ovens. In addition, there are 15 gravity casting workstations equipped with automatic and semi-automatic machines, part of them standard and part of them specifically designed for peculiar applications.

Die-casting department

We are equipped with presses up to 1000T that can produce castings from 5 grams up to 20 kilos, fully automatic and equipped with robots and automatic lubrifcation; the producing cycle is completed by trimming, deburring, refinishing and plansifter sanders.