ALUMINIUM, ALWAYS A GOOD CHOICE

Loose aluminum flanges, for pressure till 10/16 bar, are a very interesting alternative to those made in other materials, thanks to the following characteristics, which are at the same time present in the aluminium:

Aluminum weighs approximately one-third of steel, providing numerous advantages in installation, maintenance, loading and unloading, and storage, along with substantial savings in transportation costs.

In most cases the physical and chemical characteristics of aluminium allow the use of these flanges without any surface preservative treatement. Optionally you can cover the flanges with a coat of epoxy paint.

The practical use of millions of G.E.A. flanges for many years has shown that the aluminum flanges of our production give an absolutely reliable hermetically joint.

Thetmal conductivity – EN 47000 – at 20°C → 130-150 W/(mk)

The temperature of our aluminum flanges is considerably lower than the one of pipes: this is because the capacity oh heat conductivity of aluminum is 3 times higher than that of carbon steel alloys and over 6 times than that of steel alloys.

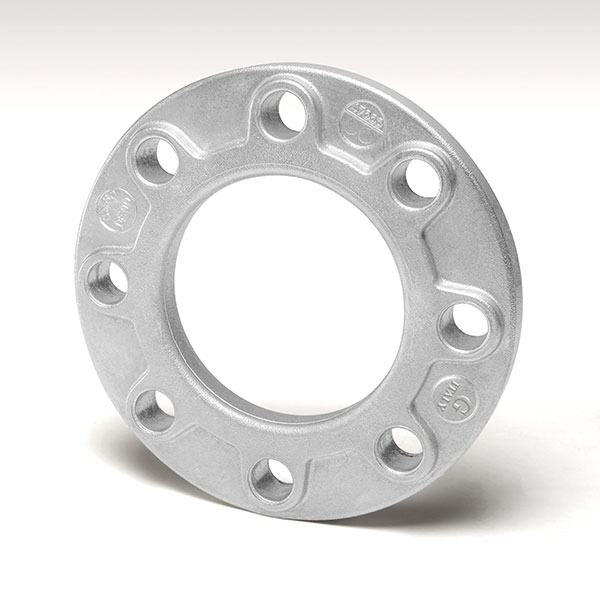

ISO-METRIC TYPE

Loose aluminium flanges for pipes with collars. Dimension compatible with EN 1092-1/02 PN10 e, sino DN150, PN 16, UNI 2223, UNI 6089 and DIN 2642 standards. Inside diameter fit for ISO and metric pipes with thickness from 1 to 3 mm.

TP-TYPE (for PE/PVC pipes)

Loose aluminium flanges for PE/PVC pipes with collars.

LITE TP-TYPE

Lap-joint aluminium flanges for collars. Dimensions compatible with EN 1092-1 PN10/16 standards. Inside diameter fit for plastic (PE) pipes.

LITE TYPE ISO-METRIC

Loose aluminium flanges for pipes with collars. Dimensions compatible with EN 1092-1/02 PN10 and, up to DN150, PN16 standards. Inside diameter fit for pipes according to ISO or metric standards.

FF-ANSI 150 TYPE

Loose (lap joint) aluminium flanges for pipes with collars. Dimensions compatible with EN1759-4 Class 150. Inside diameter fit for pipes according to ISO standards.

PN6 TYPE

Loose aluminium flanges for pipes with collars. Dimensions compatible with EN 1092-1/02 PN6 standards.

BLIND TYPE

Blind aluminium flanges. Dimensions compatible with EN 1092-1/05 PN10, UNI 6092 and DIN 2527 standards.

BLIND PN16 TYPE

Blind aluminium flanges. Dimensions compatibles with standards UNI 6093 PN16.

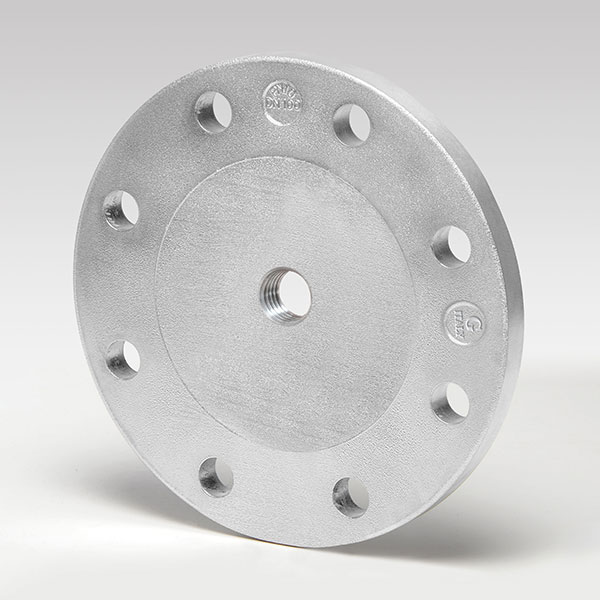

FF-BG PN10 TYPE

Threaded aluminium flanges. Dimensions compatible with EN 1092-1 PN10/16 standards. Inside diameter threaded acccording to ISO 228/1 or NPT ac- cording to ANSI/ASME B1.20.1.

FF-G PN10 TYPE

Threaded aluminium flanges. Dimensions compatible with standards EN 1092-1 PN10/16 Inside diameter threaded acccording to UNI ISO 228/1.